UV LASER MARKING MACHINE

Product Description

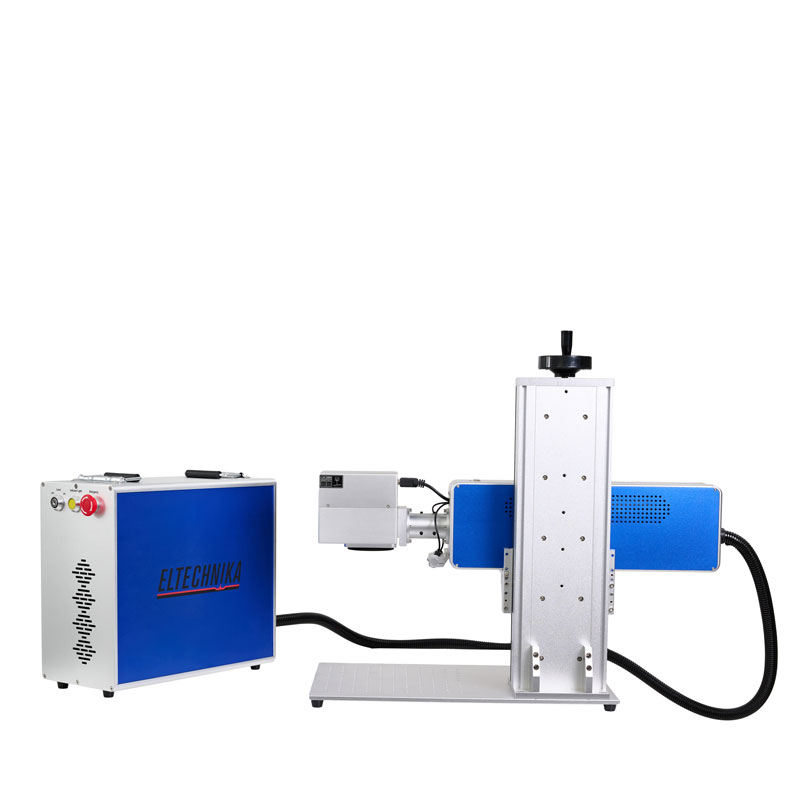

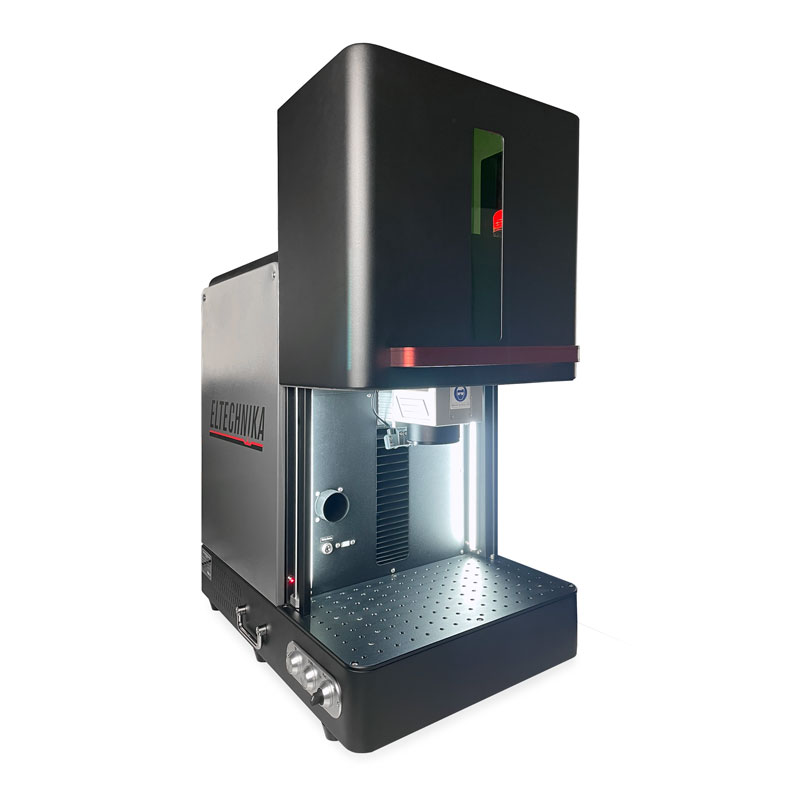

Laser marking system equipped with a galvanometric laser head and UV laser resonator. As the name implies, UV Galvo lasers use ultraviolet light to mark various materials; in this process, the UV light does not heat the surface as FIBER or CO2 lasers do. UV lasers are ideal for almost all materials, including glass, crystals, metals, plastics, silicon and others. UV is particularly effective in marking glass/crystals and can give extremely high quality results. UV lasers are 3-5 times faster than traditional glass marking methods. This leads to higher productivity, lower labour costs and improved profitability for your business. Focusing on UV laser machines has been further improved - instead of the usual two red dots, it's now even simpler with red lines that set the right height faster than ever before. To mark cylindrical surfaces, use the rotary axis for which the laser is designed. Thanks to its high quality laser source, it has a lifetime of up to 20 000 hours.

Key features:

- Industry-leading laser source

Thanks to its world-famous JPT laser source, this unit offers stable and reliable operation with a lifetime of up to 20 000 hours. - Head scanner

Our standard ZBTK ensures excellent accuracy and stable edge-to-edge marking thanks to its high-quality silicone mirrors.

Sino-Galvo scanners offer faster engraving speeds. - Compatible with LightBurn software

This EzCAD-based laser works with the latest LightBurn head features on Windows, macOS and Linux, making it easy to create even the most complex patterns. - Red laser marker

Visible red laser lines help you focus the laser quickly and easily. The integrated red laser marker allows you to quickly determine the right height to start work. - High quality branding

The UV laser is particularly effective for marking glass or crystals. - Fast

Several times faster than conventional marking methods, resulting in high productivity and profitability. - Secure

At no extra cost, we offer the option of having an access key to activate the laser. The access key prevents unauthorised persons from using the laser. A very good choice for families with young children. - Compatible with rotary

Our engraver has built-in support for rotary attachments with 4-pin connectors. Enjoy easy and fast engraving of rings, bracelets, cups, tubes and other cylindrical surfaces.

SPECIFICATION | |

| Laser Source | JPT Seal - 355 - 3SE/3C/5C/10S |

Laser Power | 3W, 5W, 10W |

| Pulse Range | 20 - 150kHz |

Engraving Speed | 0 - 8000mm/s |

| Minimum Line Thickness | <0.01mm |

Laser Wavelength | 355nm |

| Working Field | 70x70mm, 110x110mm, 150x150mm, 175x175mm, 200x200mm, 300x300mm |

Cooling | Air / Water |

| Laser Source Lifetime | Up to 20 000 hours |

Power Supply Voltage | 230VAC, 50-60Hz |

| Energy Consumption | <= 500W |

Temperature / Humidity Level | 0~35°C / 10~95% |

| Machine Tool Dimensions and Weight | 660x240x500mm, 35kg |

Software | EzCAD (Recommended LightBurn - Galvo, separate paid license) |

| Supported File Formats | AI, PLT, DXF, BMP, DWG, DXP, PNG, JPG etc. |

Suitable Materials | Almost all (organics, solids, glass, crystals, metals, plastics, silicon, etc.) |

| Rotary | Additional Option (for rings, bracelets, glasses, etc.) |